The Best Fluffy Pancakes recipe you will fall in love with. Full of tips and tricks to help you make the best pancakes.

Table of Contents

- 1 The Hidden Psychology of Emergency Responses (And Why Your Brain Is Your Worst Enemy)

- 2 Legal Requirements vs. Real-World Practicality: What the Codes Don’t Tell You

- 3 Mapping Your Kitchen’s “Danger Zones” (And Where to Place Equipment)

- 4 The Most Overlooked (But Critical) Equipment Placement Mistakes

- 5 Designing for Human Behavior (Not Just Code Compliance)

- 6 Training: Because the Best Equipment Is Useless If No One Knows How to Use It

- 7 Real-World Examples: When Placement Saved Lives (And When It Didn’t)

- 8 The Hidden Costs of Poor Safety Placement

- 9 Action Plan: How to Audit (And Fix) Your Kitchen’s Safety Placement

- 10 FAQ: Your Burning Questions About Safety Equipment Placement

- 11 Final Thought: What’s Your Kitchen’s “Oh Sh*t” Moment?

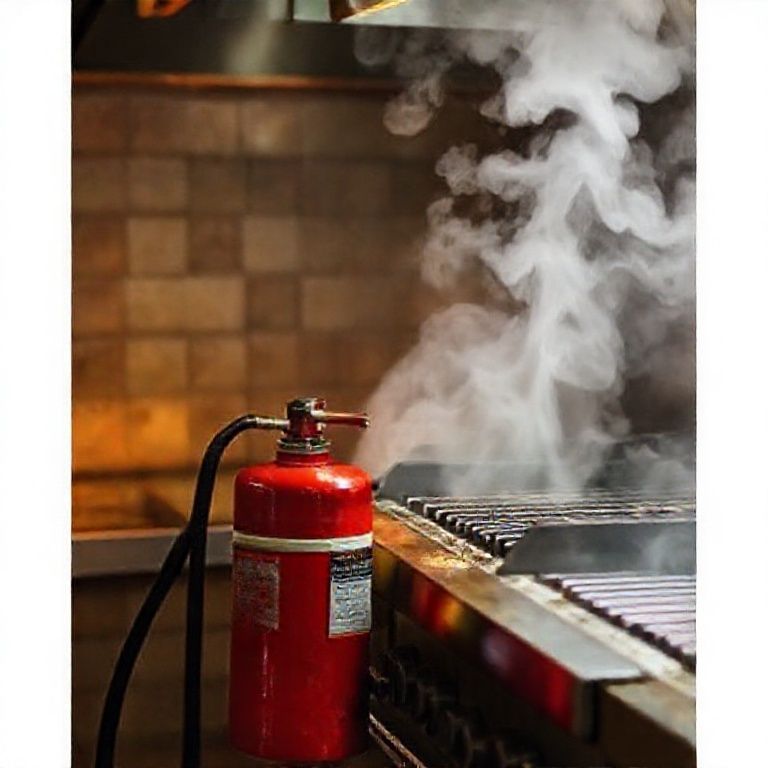

I’ll admit it, I used to think fire extinguishers and first-aid kits were just boxes you checked off during health inspections. That changed the night a grease fire at a downtown Nashville diner I was consulting for turned what should’ve been a 30-second response into a chaotic scramble because the Class K extinguisher was buried behind a stack of delivery boxes. Safety equipment placement isn’t about compliance; it’s about split-second decisions when adrenaline is high and logic is low. And in a commercial kitchen, where open flames, sharp blades, and scalding liquids coexist in a high-pressure ballet, those seconds matter more than most of us realize.

Here’s the thing: we obsess over knife skills, recipe costs, and Yelp reviews, but how often do we *really* audit where our safety gear lives? I’ve walked into kitchens where the eyewash station was installed next to the fryer (because “it was the only open wall space”), or where the fire blanket was mounted above the grill, directly in the plume of smoke you’d never see through in an emergency. These aren’t hypotheticals; they’re real oversights I’ve seen in places that *passed* their last inspection. Passing ≠ prepared.

This article isn’t just a checklist (though I’ll give you one). It’s about rethinking how we integrate safety into the *flow* of a kitchen, not as an afterthought, but as part of the design. We’ll cover the psychology of panic (why your brain betrays you in emergencies), the hidden costs of poor placement (spoiler: it’s not just fines), and how suppliers like Chef’s Deal-who offer free kitchen design consultations, can help bake safety into your layout from day one. Because here’s the truth: A kitchen designed for efficiency but not safety is like a sports car with no brakes.

By the end, you’ll know:

- How to map your kitchen’s “danger zones” and position equipment for instinctive access

- The legal requirements you *might* be missing (hint: OSHA and NFPA codes aren’t just suggestions)

- Why “out of sight, out of mind” is the enemy of safety, and how to fight it

- Real-world examples of placements that saved lives (and ones that didn’t)

- How to train your team to *see* safety equipment before they need it

-

The Hidden Psychology of Emergency Responses (And Why Your Brain Is Your Worst Enemy)

1. The “Freeze-Fight-Flight” Problem

Let’s start with an uncomfortable truth: In an emergency, your brain doesn’t rise to the occasion, it reverts to training. Or worse, to panic. Studies on workplace emergencies show that untrained individuals take an average of 10–20 seconds just to *recognize* a threat, then another 5–10 to decide how to act. In a grease fire, that’s the difference between a contained incident and a five-alarm disaster.

Here’s what happens in those critical seconds:

- Tunnel vision: Your peripheral vision narrows by up to 70%, meaning you won’t “see” that fire extinguisher if it’s not in your direct line of sight.

- Auditory exclusion: You might not hear alarms or shouts if you’re focused on the threat (ever noticed how everything goes quiet in a crisis?).

- Motor skill degradation: Fine movements (like unhooking a fire blanket) become clumsy under stress.

So when I say placement needs to be instinctive, I mean it literally. If your team has to *think* about where the first-aid kit is while blood is gushing, you’ve already lost. The solution? Design for muscle memory. Place equipment where hands go naturally, near prep stations, along exit paths, at eye level. And no, that doesn’t mean slapping a fire extinguisher on every wall. It means studying how your team moves and putting gear in their “flow paths.”

2. The “Invisible Gorilla” Effect

You’ve probably heard of the famous psychology experiment where people watching a basketball game miss a guy in a gorilla suit walking through the frame. That’s inattentional blindness, and it’s rampant in kitchens. When chefs are focused on tickets, they literally won’t see hazards, or safety equipment, unless it’s *impossible* to ignore.

I saw this firsthand at a seafood restaurant in Charleston. Their Class K extinguisher was mounted behind the expediter’s station-“so it wouldn’t clutter the line,” the owner told me. Problem? During a rush, the expediter’s station becomes a blind spot. When a saute pan flared up, the line cook grabbed the *wrong* extinguisher (a Class A) because it was the one he saw daily. **Visibility isn’t just about being seen; it’s about being seen *when it matters*.

Fix this by:

- Using color contrast (red extinguishers on white walls, not stainless steel).

- Adding tactile cues (e.g., a textured strip on the floor leading to the eyewash station).

- Placing equipment where eye contact is inevitable-like above the pass-through or next to the POS system.

-

Legal Requirements vs. Real-World Practicality: What the Codes Don’t Tell You

3. OSHA and NFPA: The Minimum Isn’t Enough

Yes, OSHA 1910.157 mandates fire extinguishers within 75 feet of any point in the kitchen, and NFPA 96 requires suppression systems over cooking equipment. But here’s what the codes don’t account for:

- Traffic patterns: A extinguisher 75 feet away is useless if it’s behind a swinging door during peak service.

- Obstructions: “Unobstructed access” in the codebook doesn’t mean “not blocked by a stack of to-go containers.”

- Human factors: Codes assume people will act rationally. (See: every viral video of someone throwing water on a grease fire.)

Take the eyewash station requirement (OSHA 1910.151). The code says it must be within 10 seconds’ reach of a hazard. But in a tight kitchen, “10 seconds” can mean weaving through three people during a Friday night rush. Pro tip: Time it. Literally. Have a staff member simulate an emergency and count how long it takes to reach each safety station. If it’s more than 10 seconds, move it.

4. The “But We Passed Inspection” Trap

I’ve lost count of how many chefs have told me, “We’re fine; the inspector didn’t say anything.” Here’s the reality: Inspectors check for compliance, not optimization. They won’t flag that your fire blanket is mounted above the grill (where smoke will obscure it) because the code only requires it to be “accessible.” They won’t note that your first-aid kit is in the office because “technically” it’s within the required distance.

A kitchen I worked with in Austin had their first-aid kit in the manager’s office, locked. Why? “So staff wouldn’t steal bandages.” The result? A line cook with a deep cut bled for 10 minutes waiting for a key. Safety equipment must be accessible to those who need it most, when they need it. If theft is a concern, try a tamper-evident seal or a small unlocked kit on the line with a larger one in the office.

Ask yourself:

- Is this placement inspector-approved or user-optimized?

- Who needs this equipment most? (Hint: It’s not always the manager.)

- What’s the worst-case scenario for accessing this? (e.g., during a power outage, with a full dining room)

-

Mapping Your Kitchen’s “Danger Zones” (And Where to Place Equipment)

5. The “Heat Map” Approach

Every kitchen has hotspots, areas where injuries or fires are statistically more likely. Instead of scattering equipment randomly, create a danger heat map. Grab a floor plan and mark:

- Red zones: High-risk areas (fryers, grills, slicers). These need immediate access to extinguishers, fire blankets, and first aid.

- Yellow zones: Moderate risk (prep stations, ovens). Secondary equipment like spill kits or burn gels should be here.

- Green zones: Low risk (dry storage, office). Basic first aid is sufficient.

For example, in a pizzeria, the wood-fired oven is a red zone. The extinguisher should be within arm’s reach of the pizza peel station, not by the prep table. In a sushi bar, the slicers and sharp knives area is red, cut-resistant gloves and a trauma kit should be right there.

Pro tip: Use painters tape to outline “safety radii” on the floor. For a fryer, draw a 3-foot circle around it. That’s your extinguisher’s home. If it’s outside that circle, move it.

6. The “Golden Triangle” of Safety Placement

Borrowing from kitchen design’s “work triangle” concept, the most critical safety equipment should form a safety triangle:

- Fire suppression: Extinguishers, blankets, and suppression system pull stations.

- First aid: Trauma kits, burn gels, eyewash stations.

- Egress: Clear paths to exits, marked with photoluminescent tape.

The goal? No matter where a crisis starts, one of these three points should be within 3–5 seconds’ reach. In a typical 1,000 sq. ft. kitchen, that means:

- A Class K extinguisher by the grill and fryer (not one for both).

- An eyewash station between the prep area and the dish pit (where chemical splashes are common).

- A first-aid kit at the pass-through (central to both FOH and BOH).

I’m torn between advocating for redundancy (“more is better!”) and simplicity (“too many extinguishers creates confusion!”). Ultimately, the right number is the minimum needed to cover all red zones without overlap. If you’re unsure, suppliers like Chef’s Deal offer free kitchen design consultations that include safety audits, they’ll help you balance compliance, cost, and practicality.

-

The Most Overlooked (But Critical) Equipment Placement Mistakes

7. Eyewash Stations: The “Set It and Forget It” Disaster

Eyewash stations are the poster child for “compliance over common sense.” I’ve seen them installed:

- Behind a door (useless if the person can’t see to open it).

- Next to the handwashing sink (contaminated by soap splatter).

- In a corner where the spray hits the wall, not the user’s face.

The fix? Test it weekly. Have a staff member simulate an eye injury and use the station. If they can’t flush their eyes for a full 15 minutes without moving, it’s in the wrong spot. And no, that plastic cover isn’t “protecting” it, it’s adding a step in an emergency. Ditch it.

8. Fire Blankets: The Invisible Hero

Fire blankets are the unsung heroes of kitchen safety, when you can find them. Too often, they’re mounted:

- Above the source of the fire (hidden by smoke).

- In a cabinet (because “it looks cleaner”).

- Without clear labeling (so new hires don’t know what it is).

Rule of thumb: Mount fire blankets at hip level, within 10 feet of any open flame, and with a glow-in-the-dark label. Why hip level? Because if your hands are burned, you can still grab it with your forearm. And yes, that means it might “clutter” your stainless steel aesthetic. Safety isn’t decorative.

9. First-Aid Kits: The “One Size Fits None” Problem

Most kitchens have a single first-aid kit, usually a cheap plastic box with Band-Aids and aspirin. Here’s why that’s a failure:

- Location: If it’s in the office, a line cook with a bleeding hand isn’t going to run across the kitchen to get it.

- Contents: A kitchen needs trauma supplies-tourniquets, hemostatic gauze, burn gel, not just adhesive bandages.

- Accessibility: Locked kits are a liability. If you’re worried about theft, install a break-glass box (like hotels use for defibrillators).

Solution: Create a tiered system:

- Line-level kits: Small, unlocked boxes at prep stations with gloves, burn gel, and bandages.

- Manager’s kit: Larger, locked kit with trauma supplies for serious injuries.

And for the love of all that’s holy, train your team on how to use a tourniquet. I’ve seen too many kitchens where the kit had one, but no one knew how to apply it.

-

Designing for Human Behavior (Not Just Code Compliance)

10. The “Path of Least Resistance” Principle

Humans default to the easiest option, even in emergencies. If the fire extinguisher is behind a stack of trays, they’ll grab the water pitcher instead. If the first-aid kit is in the office, they’ll wrap a cut in a napkin. Your job is to make the *right* choice the *easiest* choice.

How?

- Remove barriers: No doors, lids, or locks between staff and safety equipment.

- Use visual cues: Red floor tape leading to extinguishers, glow-in-the-dark signs.

- Leverage habits: Place hand sanitizer next to the first-aid kit so staff see it daily.

11. The “New Hire Test”

Here’s a brutal but effective audit: Bring in someone who’s never worked in your kitchen and ask them to find each piece of safety equipment in under 30 seconds. If they can’t, your placement fails the real-world test.

I did this in a brewery kitchen in Denver. The new hire found the fire extinguisher (good) but missed the eyewash station entirely because it was tucked behind the walk-in door. If a stranger can’t find it, your team won’t in a crisis.

12. The “Night Shift” Challenge

Ever notice how accidents happen more often on late shifts? Fatigue, fewer staff, and dimmer lighting all play a role. Audit your safety placement during the shift when it’s least ideal:

- Are exit signs visible with only emergency lighting?

- Can someone with a burn reach the first-aid kit one-handed?

- Is the fire blanket accessible if the grill is on fire and blocking the path?

Fix: Add photoluminescent markings (glow-in-the-dark) to extinguishers, exits, and first-aid kits. They’re cheap and could save a life when the power’s out.

-

Training: Because the Best Equipment Is Useless If No One Knows How to Use It

13. The “Muscle Memory” Drill

Fire drills aren’t just for schools. Run monthly “safety sprints” where staff practice:

- Grabbing the extinguisher with their eyes closed (to simulate smoke).

- Applying a tourniquet to a (fake) bleeding arm.

- Finding the eyewash station from any point in the kitchen.

Why? Because in a crisis, you don’t rise to the occasion, you fall to your highest level of training. If your team has never touched the fire blanket, they won’t in an emergency.

14. The “Why” Behind the “What”

Don’t just tell staff where the equipment is, explain why it’s there. For example:

- “This Class K extinguisher is by the fryer because water will spread a grease fire.”

- “The eyewash is here because chemical splashes from the dish pit happen most often at this station.”

When people understand the logic behind placement, they’re more likely to maintain it (and less likely to block it with a case of oil).

15. The “Chef’s Deal” Advantage

If you’re designing a new kitchen or renovating, suppliers like Chef’s Deal can be game-changers. They don’t just sell equipment, they offer free kitchen design services that include safety audits. Their team will:

- Map danger zones based on your menu (e.g., a wok station needs different suppression than a grill).

- Recommend placement that balances workflow efficiency and safety access.

- Provide professional installation so equipment is mounted correctly (no DIY disasters).

- Offer financing options if you need to upgrade suppression systems or add redundant safety gear.

I’m not saying you eed a consultant, but if you’re starting from scratch, their expertise can save you from costly mistakes. (And no, this isn’t a paid endorsement, I’ve just seen too many kitchens where a $50 consultation could’ve prevented a $50,000 lawsuit.)

-

Real-World Examples: When Placement Saved Lives (And When It Didn’t)

16. The Success: A Nashville BBQ Joint

A smoker fire at a local BBQ spot could’ve been catastrophic, but because the Class K extinguisher was mounted on the smoker cart itself (not 20 feet away on the wall), the pitmaster put it out in seconds. Lesson: For mobile equipment (like food trucks or catering setups), safety gear should move with the hazard.

17. The Failure: A Boston Seafood Restaurant

A chef suffered a severe burn when a pot of boiling lobster water tipped. The first-aid kit was in the office, locked. By the time a manager arrived with the key, the chef was in shock. The kitchen had passed its last three inspections. Compliance ≠ preparedness.

18. The Close Call: A Vegas Hotel Kitchen

A grease fire in a hotel kitchen spread quickly because the suppression system’s pull station was behind a stack of trays. The line cook who tried to activate it suffered smoke inhalation. Takeaway: Audit your placement during peak service, not during a slow afternoon.

-

The Hidden Costs of Poor Safety Placement

19. Beyond Fines: The Real Price Tag

We all know OSHA fines hurt, but the real costs of poor safety placement are:

- Downtime: A kitchen closed for an investigation loses thousands per day.

- Reputation: A viral video of a fire or injury can tank your Yelp rating overnight.

- Insurance: Premiums skyrocket after claims. Some insurers now require safety audits before renewing policies.

- Staff turnover: Cooks remember kitchens where they felt unsafe, and they talk.

I worked with a taco shop in Austin that saved $300 by buying a cheaper extinguisher cabinet. After a small fire, the cabinet’s flimsy latch failed, and the extinguisher fell, cracking the handle. The $300 “saving” cost them $3,000 in downtime and repairs. Cheaping out on safety is like saving on brake pads.

20. The Domino Effect

Poor placement doesn’t just fail in emergencies, it creates them. Example:

- A fire blanket mounted above the grill gets coated in grease, making it useless when needed.

- An extinguisher blocked by a prep table forces staff to reach awkwardly, leading to dropped equipment (and injuries).

- A first-aid kit in a hot area (like near the dishwasher) causes supplies to degrade faster.

Audit tip: Walk your kitchen with a critical eye. If equipment is in a place where it can be damaged, contaminated, or obscured, move it.

-

Action Plan: How to Audit (And Fix) Your Kitchen’s Safety Placement

Step 1: The “Red Light/Green Light” Walkthrough

Grab a notepad and walk your kitchen. For each piece of safety equipment, ask:

- Visibility: Can I see it from the highest-risk area it serves? (If not, move or add signage.)

- Accessibility: Can I reach it in 3–5 seconds with one hand? (Test this.)

- Obstructions: Is there anything (doors, equipment, stacks of boxes) that could block access during service?

- Condition: Is it clean, functional, and fully stocked? (Check expiration dates!)

Step 2: The “Worst-Case Scenario” Test

Simulate emergencies during peak service:

- Block an exit with a “crowd” (staff playing customers). Can everyone evacuate?

- Turn off the lights. Can staff find exits and extinguishers?

- Have a staff member “injure” their dominant hand. Can they access first aid?

Step 3: The “Chef’s Deal” Consult (If You’re Starting Fresh)

If you’re designing a new kitchen, take advantage of suppliers who offer free design services. Companies like Chef’s Deal will:

- Create a layout that balances workflow and safety.

- Recommend suppression systems tailored to your cooking methods (e.g., wood-fired vs. gas).

- Provide professional installation to ensure equipment is mounted correctly (no DIY disasters where the fire blanket falls off the wall mid-emergency).

Even if you’re not buying equipment from them, their consultations can spot blind spots you’d miss. (And if you are buying, their competitive pricing and financing options make upgrades more manageable.)

Step 4: The 30-Day Challenge

For the next month, make safety placement a daily topic:

- Start each shift with a 60-second “safety spot” (e.g., “Today, let’s all note where the nearest extinguisher is”).

- End each shift with a 10-second audit: Is everything accessible? Restock if needed.

- Reward staff who point out placement issues (e.g., “Hey, this fire blanket is blocked by the new shelf”).

Why? Because safety isn’t a one-time fix, it’s a culture.

-

FAQ: Your Burning Questions About Safety Equipment Placement

Q: How often should I replace or inspect safety equipment?

A: Here’s the breakdown:

- Fire extinguishers: Inspect monthly (check pressure, seals, and accessibility). Professionally service annually. Replace every 6–12 years (or after use).

- First-aid kits: Check weekly for used/depleted items. Replace expired items (like antiseptic wipes) every 1–2 years.

- Eyewash stations: Test weekly to ensure water flow. Flush monthly to prevent sediment buildup.

- Fire blankets: Inspect quarterly for tears or grease buildup. Replace if damaged.

Pro tip: Set phone reminders or tie inspections to existing routines (e.g., “Every time we change the fryer oil, check the extinguisher”).

Q: What’s the one piece of safety equipment most kitchens overlook?

A: A dedicated trauma kit for severe cuts. Most first-aid kits have Band-Aids and antiseptic, but a deep knife wound needs hemostatic gauze (like QuikClot) and a tourniquet. I’ve seen line cooks nearly bleed out waiting for EMS because the kitchen only had adhesive bandages. Spend the $50-it’s not if you’ll need it, but when.

Q: How do I convince my boss/owner to invest in better safety placement?

A: Frame it in terms of risk vs. cost:

- Downtime: “If we’re closed for a day after a fire, we lose $X in sales.”

- Insurance: “Our premiums could drop Y% with a safety upgrade.” (Call your insurer, they often offer discounts for suppression systems or training.)

- Staff retention: “Turnover costs us $Z per employee. Safety is a selling point for hiring.”

- Legal protection: “If OSHA fines us for a blocked extinguisher, it’s $14,000+ per violation.”

Bonus: Offer to phase upgrades. Start with low-cost fixes (moving extinguishers, adding signs) and build to bigger investments (suppression systems).

Q: What’s the biggest mistake you see in kitchen safety layouts?

A: Assuming “close enough” is good enough. I can’t count how many times I’ve heard, “It’s only 10 feet away, that’s fine!” But in a kitchen, 10 feet might as well be a mile if there’s a crowd, smoke, or panic. The right distance is the distance your slowest, most stressed employee can cover in 3–5 seconds.** Measure it. Time it. And if it’s not fast enough, fix it.

-

Final Thought: What’s Your Kitchen’s “Oh Sh*t” Moment?

Every kitchen has one, that heart-stopping second when a fire flares, a knife slips, or a pot tips. The difference between a near-miss and a disaster often comes down to where the right tool was when it was needed.

So here’s your challenge: Pick one piece of safety equipment in your kitchen right now. Time how long it takes to access it during a rush. Then ask yourself: If this were an emergency, would that be fast enough?

If the answer’s no, you’ve got work to do. And if you’re not sure where to start, remember: Suppliers like Chef’s Deal offer free consultations to help design kitchens where safety isn’t an afterthought, it’s part of the flow. Because at the end of the day, the best safety equipment isn’t the one that looks good on an inspection sheet. It’s the one that’s there when you need it.

Now go audit your fire blanket. I’ll wait.

@article{why-safety-equipment-placement-in-commercial-kitchens-is-more-critical-than-you-think-and-how-to-get-it-right,

title = {Why Safety Equipment Placement in Commercial Kitchens Is More Critical Than You Think (And How to Get It Right)},

author = {Chef's icon},

year = {2025},

journal = {Chef's Icon},

url = {https://chefsicon.com/the-importance-of-safety-equipment-placement-in-commercial-kitchens/}

}